How to Choose the Best Medical Packaging Solutions for Your Needs?

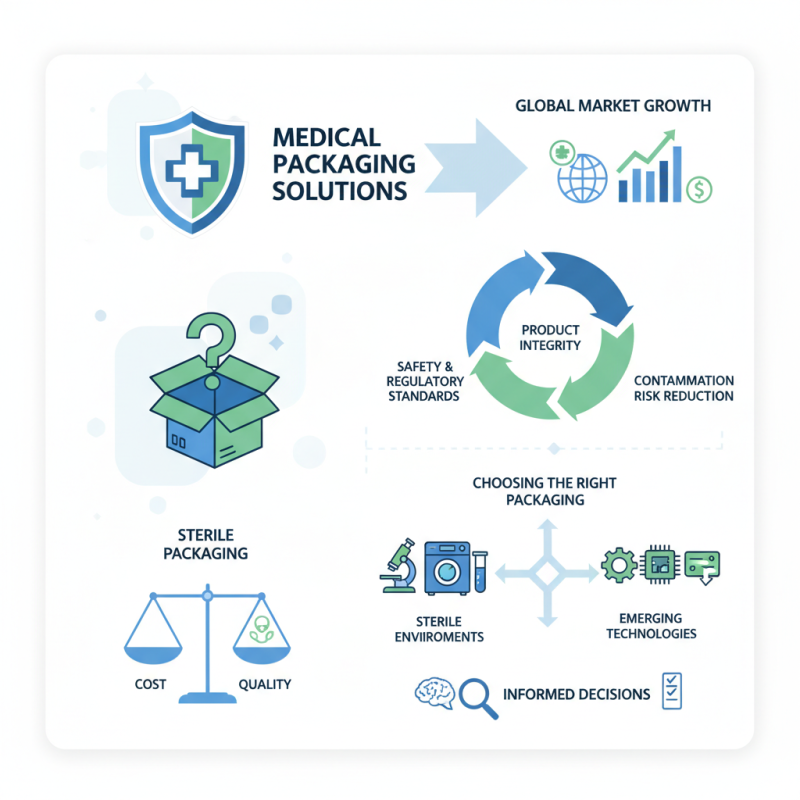

In the healthcare industry, the importance of selecting the right medical packaging solutions cannot be overstated. According to a report by MarketsandMarkets, the global medical packaging market is expected to reach $23.5 billion by 2027, growing at a CAGR of 6.2%. This growth underscores the increasing need for effective packaging that meets safety and regulatory standards while ensuring product integrity.

Medical packaging solutions play a crucial role in protecting sensitive products. A well-designed package can reduce contamination risks and ensure shelf life. However, not all packaging options are suitable for every medical device or pharmaceutical product. Understanding the specific needs of each application is vital. For instance, sterile environments require packaging that can withstand rigorous sterilization processes.

Moreover, the selection process can often be daunting. Many healthcare providers grapple with balancing cost and quality. They may also overlook emerging technologies that offer better protection. As stakeholders navigate these challenges, they must prioritize the right packaging to enhance safety and efficacy. A thoughtful approach will aid in making informed decisions about medical packaging solutions.

Understanding the Importance of Medical Packaging in Healthcare Industry

Medical packaging plays a crucial role in the healthcare industry. It ensures that medical products are protected during transportation and storage. Patients depend on the integrity of these packages for safety. Each material must withstand various conditions. From temperature fluctuations to physical impacts, the packaging's resilience is vital.

Additionally, effective labeling is key. Clear instructions and expiration dates are necessary for both healthcare professionals and patients. Misleading or unclear information can lead to significant risks. However, too much information can overwhelm the user. Striking the right balance is challenging yet essential.

Moreover, sustainability is becoming increasingly important. Many healthcare providers are seeking eco-friendly options. The transition can be slow and requires thoughtful planning. Some materials may not yet be recyclable or reusable. Each choice impacts the environment and the bottom line. It's a complex decision that requires careful consideration.

Evaluating Different Types of Medical Packaging Materials and Their Uses

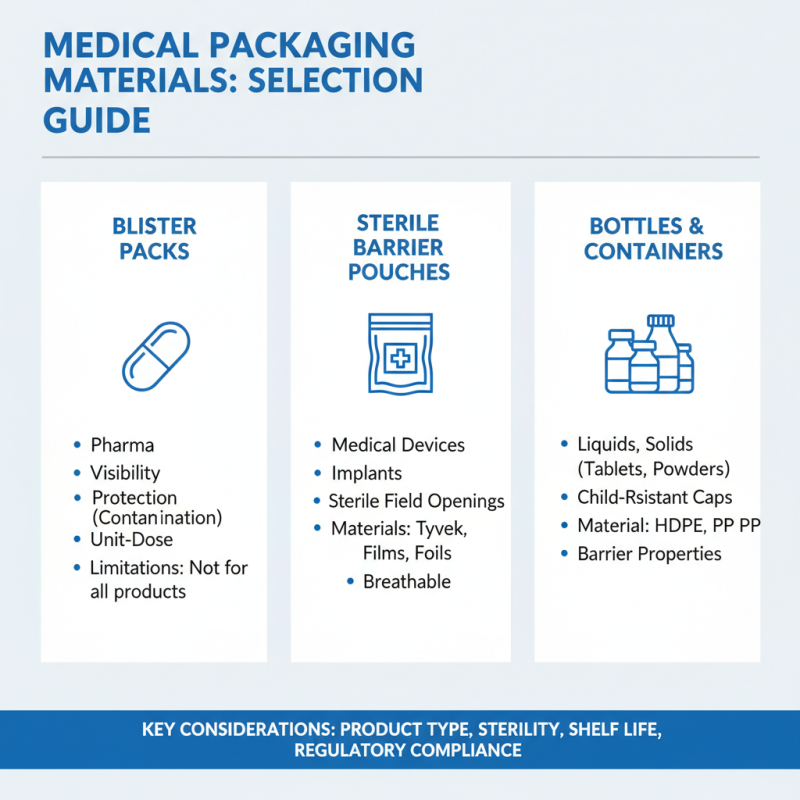

Choosing the right medical packaging materials is essential for ensuring product integrity and safety. Various options are available, each with specific applications. For instance, blister packs are popular for pharmaceuticals. They provide visibility and protection against contamination. However, they may not be suitable for all product types.

Flexible pouches are another common choice. They are lightweight and can be easily sealed. Many materials, like polyethylene or laminate films, can be used. But, the choice of material affects barrier properties. It’s crucial to evaluate the product requirements carefully. Sometimes, compromises on barrier protection can lead to issues.

Rigid containers offer durability and are often used for sterile items. Glass and certain plastics provide excellent protection. However, these options can be heavier and less versatile. Stocking various types of packaging may seem unnecessary but can address diverse needs. Evaluations may reveal gaps in current packaging solutions, pointing to areas requiring improvement.

Assessing Regulatory Compliance and Standards in Medical Packaging Solutions

When considering medical packaging solutions, regulatory compliance is crucial. Many standards exist to ensure safety and efficacy. These include ISO standards, FDA regulations, and specific guidelines for various medical products. Each standard possesses its own set of requirements. Understanding these can be overwhelming. However, failing to comply can lead to serious consequences, including product recalls.

Tips: Keep updated on relevant regulations. Regularly check official resources. Documentation is key. Maintain clear records of compliance to ensure transparency.

Evaluating each packaging solution against these standards is vital. Look for materials that resist contamination. Design should facilitate safe handling and storage. It's crucial to consider the sustainability of materials as well. Are they recyclable? Such details can impact your compliance rating.

Tips: Collaborate with packaging experts. Seek advice from consultants who specialize in regulatory matters. Create a checklist of required standards for your specific product type. Working together can streamline the process.

How to Choose the Best Medical Packaging Solutions for Your Needs? - Assessing Regulatory Compliance and Standards in Medical Packaging Solutions

| Packaging Type | Material Used | Regulatory Compliance | Sterilization Methods | Applications |

|---|---|---|---|---|

| Blister Packaging | PVC, PET | ISO 11607 | Gamma, ETO | Single-use Devices |

| Pouches | Polyethylene, Tyvek | ISO 11135 | Steam, Plasma | Surgical Instruments |

| Vials and Bottles | Glass, Plastic | USP, FDA | Dry Heat, ETO | Pharmaceuticals |

| Shrink Sleeves | PVC, PETG | FDA Compliant | None | Diagnostic Kits |

| Trays | Polypropylene, Polystyrene | ISO 13485 | Steam, Radiation | Surgical and Dental Products |

Analyzing Cost-Effectiveness of Various Medical Packaging Options

When evaluating medical packaging options, cost-effectiveness is crucial. Various materials can lead to significant differences in pricing. For instance, plastic is often cheaper but may not provide the same level of protection as glass or aluminum. It’s essential to analyze how long the packaging will last and how it will be used. Some packages might offer lower upfront costs but could incur higher shipping or storage expenses over time.

Consider the purpose of the packaging. Is it meant for shipping, storage, or both? A package designed for prolonged shelf life might cost more initially but save money in the long run. Take time to assess durability, environmental impact, and compliance with regulations. These factors can ultimately influence the total cost of ownership.

Be mindful of potential compromises. A less durable solution may save money but could lead to damaged products and lost sales. Reflect on the trade-offs between immediate savings and long-term functionality. Balancing cost and quality is not always straightforward. It often requires thoughtful analysis and a willingness to explore various options before deciding.

Identifying Trends in Technology and Innovation in Medical Packaging

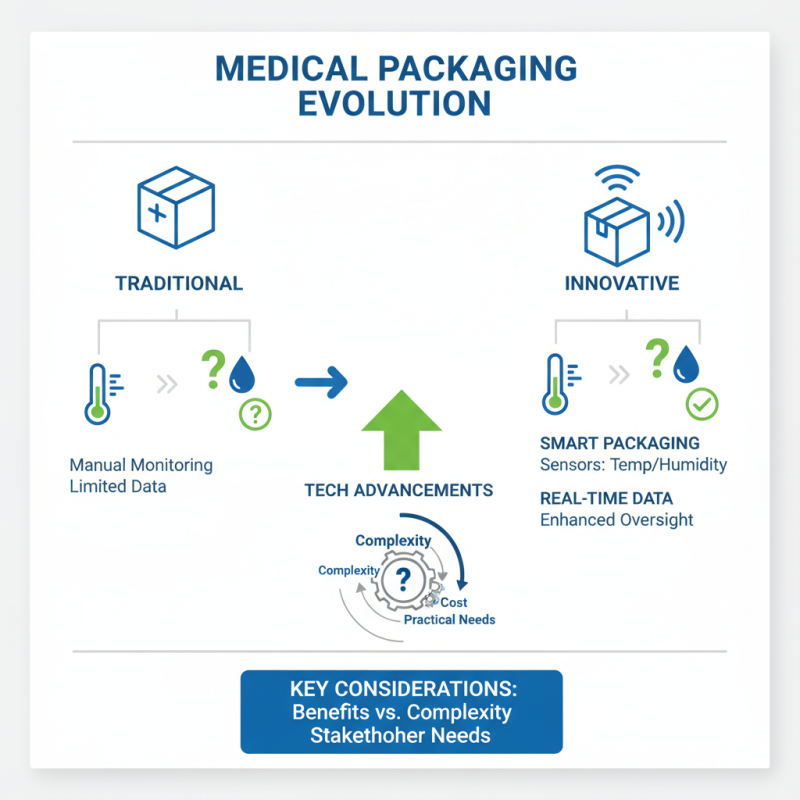

The landscape of medical packaging is rapidly evolving. Innovations in technology are influencing how products are packaged and delivered. For instance, smart packaging features sensors that monitor temperature and humidity. This gives manufacturers real-time data about product conditions. Such advancements might seem beneficial, yet they add complexity. Stakeholders must assess whether the added technology truly meets their practical needs.

Sustainability is also a growing trend. Many companies are looking for eco-friendly materials to reduce waste. Biodegradable or recyclable options are gaining popularity. However, while they are environmentally friendly, the cost can be higher. This creates a dilemma for budget-conscious businesses. The balance between cost and sustainability is crucial.

Technology integration poses other challenges. Not all organizations have the infrastructure for smart packaging. Training staff to handle new technologies can be daunting. The reliance on technology raises questions about security and data privacy. Organizations must think critically about these lingering issues as they seek innovative solutions.

Related Posts

-

Top Packaging Machines Trends to Watch in 2025 for Your Business

-

Top European Packaging Solutions for 2025: Trends and Innovations

-

Top 10 Meat Packaging Solutions for Freshness and Safety

-

Top 10 Trends Shaping the Future of the Packaging Equipment Market

-

Top Solutions Pack: Unlocking Effective Strategies for Business Success

-

Top Press Solutions in 2025 for Effective Public Relations Management