What is Packaging Equipment and How Does It Impact Industries?

Packaging equipment plays a crucial role in various industries. It refers to the machines and tools used for packaging products. This equipment ensures that goods are appropriately sealed and protected for distribution. However, there are some challenges associated with packaging equipment.

Many companies are investing in advanced packaging solutions. These solutions can improve efficiency and reduce waste. However, not all businesses can afford the latest technology. Smaller companies may struggle to keep up. This leads to a disparity in production capabilities among different players in the market.

Properly functioning packaging equipment can enhance product appeal. It also influences shelf life and customer satisfaction. Yet, companies must regularly evaluate their machinery. Outdated equipment can hinder growth. Businesses need to balance cost and innovation to stay competitive. As industries evolve, the impact of packaging equipment grows ever more significant.

What is Packaging Equipment?

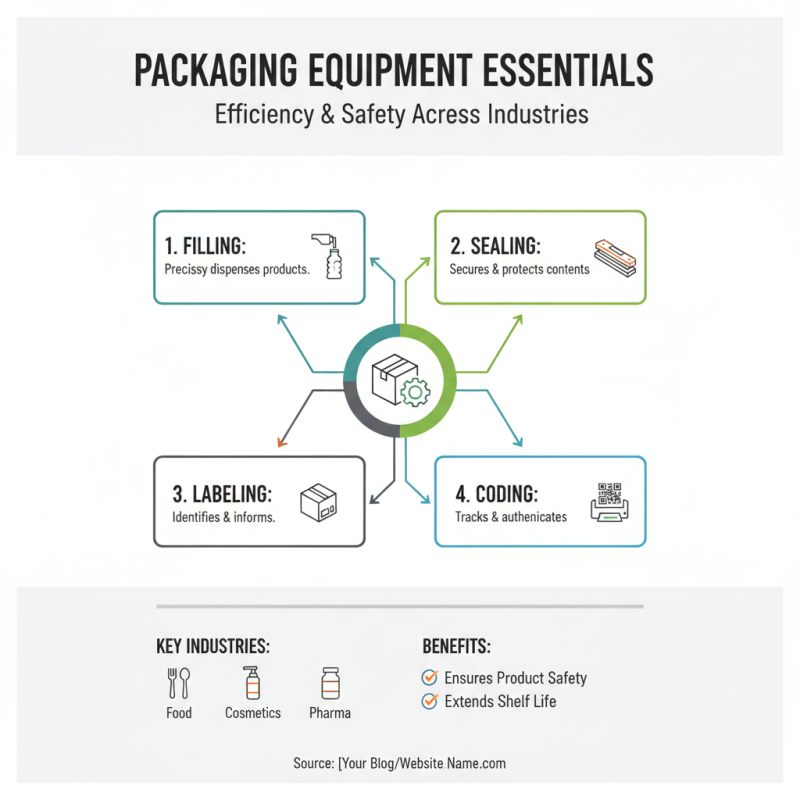

Packaging equipment refers to machinery used to package products efficiently. This equipment can include machines for filling, sealing, labeling, and coding. It's essential for industries like food, cosmetics, and pharmaceuticals. Proper packaging ensures safety and extends shelf life. Each type of equipment plays a specific role in this process.

Companies sometimes overlook the importance of investing in high-quality packaging equipment. This can lead to increased waste and lower product quality. Productivity may suffer if the machinery is outdated or poorly maintained. Workers often face challenges when operating complex machines, leading to errors. Adjustments and training may be necessary to optimize performance.

In addition, the environmental impact of packaging materials can’t be ignored. Many companies are shifting towards sustainable options. They reconsider their choices to minimize waste. However, finding a balance between functionality and sustainability remains complex. Some equipment may not adapt easily to eco-friendly materials, creating hurdles.

Types of Packaging Equipment Used in Various Industries

In various industries, packaging equipment plays a crucial role in enhancing product quality and efficiency. Common types include filling machines, sealing machines, and labeling machines. Each type is designed for specific tasks, ensuring that products are packaged correctly for consumer use. For instance, filling machines precisely dispense liquids into bottles, while sealing machines secure package integrity.

One tip for choosing the right equipment is to assess your product's characteristics. Viscosity, temperature, and the packaging format all impact the type of machinery needed. Additionally, consider the production speed. High-demand products require faster equipment. This often requires a balance between speed and quality.

It's important to note that investing in packaging equipment can be expensive. Companies may face difficulties when selecting machines that meet their evolving needs. Regular maintenance is essential to keep the equipment running optimally. Ultimately, understanding the varied types of packaging equipment can help businesses make informed decisions that enhance their operational efficiency.

What is Packaging Equipment and How Does It Impact Industries? - Types of Packaging Equipment Used in Various Industries

| Type of Packaging Equipment | Industry | Purpose | Key Features |

|---|---|---|---|

| Fillers | Food Industry | To fill containers with liquid or semi-solid products | Accurate volume control, automated operation |

| Labeling Machines | Beverage Industry | To apply labels on bottles or containers | High-speed labeling, adjustable for various container sizes |

| Cartoning Machines | Pharmaceutical Industry | To package products into cartons | Compact design, easy integration with other equipment |

| Sealing Machines | Cosmetics Industry | To secure packages by sealing them | Heat sealing, vacuum sealing options |

| Wrapping Machines | Electronics Industry | To wrap products for protection during shipping | Automatic film application, adjustable tension control |

The Role of Packaging Equipment in Production Efficiency

Packaging equipment plays a crucial role in production efficiency across various industries. By automating packaging processes, companies can significantly reduce labor costs. According to a report by PMMI, the Association for Packaging and Processing Technologies, nearly 30% of manufacturers reported that automation has improved their overall productivity. This efficiency allows businesses to allocate resources more effectively, leading to increased output.

However, not all packaging solutions yield positive results. Inefficient equipment can slow down production lines and increase waste. A study by Packaging Strategies indicated that about 20% of companies experienced downtime due to outdated machinery. This underscores the need for consistent evaluation and investment in the latest packaging technologies to remain competitive.

Streamlined packaging processes often enhance product shelf life and reduce spoilage. The Proper Equipment Report highlights that adopting automated systems can reduce food waste by up to 25%. Still, companies must remain vigilant. A poorly implemented system can disrupt workflow and cause product damage. Regular training and maintenance are essential to maximize the benefits of packaging equipment.

Impact of Packaging Equipment on Product Quality and Safety

Packaging equipment plays a crucial role in ensuring product quality and safety. It is designed to protect items from contamination, damage, and spoilage. Effective sealing and labeling prevent air and moisture from affecting sensitive products. This adds an extra layer of safety during transport and storage. Without proper packaging, even the highest quality product can become compromised.

In many industries, inconsistencies in packaging processes can lead to significant issues. Sometimes, equipment malfunctions can result in faulty seals. This opens the door to bacteria, which poses serious health risks. Additionally, poor labeling can lead to customer confusion and dissatisfaction. Reflecting on these challenges highlights the importance of investing in reliable machinery.

Despite advancements, there remain gaps in packaging technology. Some materials may still not provide adequate protection against environmental factors. Ongoing research is needed to develop better options. Partnering with experts in the field could help industries enhance their packaging standards. Quality assurance should always be a priority, as it directly affects consumer trust and brand reputation.

Future Trends in Packaging Equipment Technology and Innovation

The world of packaging equipment is evolving. Innovations in technology are shaping how products are packaged and delivered. Automation is becoming more prevalent, enabling faster production. Smart packaging solutions are on the rise, offering real-time tracking and enhanced safety features.

There is a growing emphasis on sustainability. More companies are exploring eco-friendly materials and processes. This shift reflects consumer preferences for environmentally responsible products. However, the challenge remains in finding a balance between functionality and sustainability. Companies must continue to innovate while keeping costs manageable.

One emerging trend is the integration of artificial intelligence. AI can optimize supply chains and improve efficiency. But, there's a risk of over-reliance on technology. Human oversight is still crucial in maintaining quality. As packaging technology advances, industries must remain adaptable and vigilant.

Related Posts

-

Top 10 Trends Shaping the Future of the Packaging Equipment Market

-

What is Packaging Equipment and How Does It Work?

-

Top US Packaging Solutions to Streamline Your Business Operations

-

How to Choose the Best Packaging Solutions for Your Business Needs

-

Top 10 US Packaging Solutions to Boost Your Business Efficiency

-

Top Press Solutions in 2025 for Effective Public Relations Management