Top Meat Packaging Solutions for Freshness and Safety in the Food Industry?

In the fast-paced food industry, ensuring freshness and safety is crucial. This is especially true for meat products. The right meat packaging solutions can make a significant difference. They help maintain quality and prevent spoilage.

Various materials and techniques are used in meat packaging. Vacuum sealing and modified atmosphere packaging are popular choices. These methods extend shelf life and preserve flavor. However, not all solutions are perfect. Some may lead to excess plastic waste, prompting a need for sustainable alternatives.

Consumers are becoming more conscious of packaging choices. They want safe and fresh options. As the industry evolves, balancing efficiency and environmental impact is vital. Meat packaging solutions must adapt to these changing demands for better outcomes.

Overview of Meat Packaging Solutions in the Food Industry

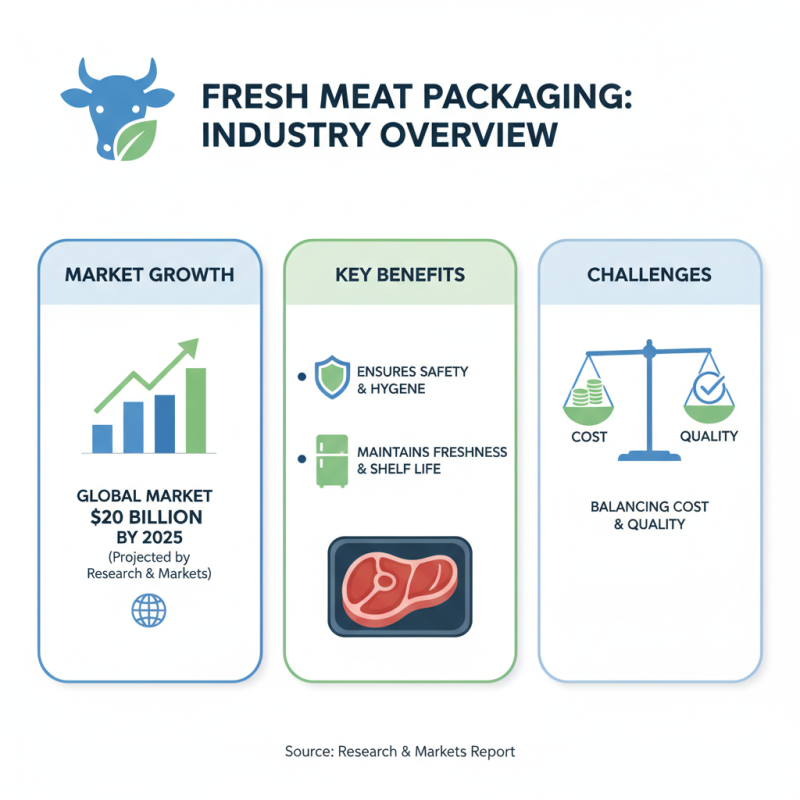

In the food industry, fresh meat packaging is crucial. According to a report by Research and Markets, the global meat packaging market is projected to reach $20 billion by 2025. This growth highlights the increasing demand for effective meat preservation solutions. Packaging helps maintain freshness and ensures safety for consumers. However, the challenge remains in balancing cost and quality.

Various packaging solutions exist, each with its unique strengths and weaknesses. Vacuum packaging is popular for extending shelf life but has limitations in breathability. Modified atmosphere packaging (MAP) can enhance visual appeal but may not be suitable for all types of meat. Consumers demand transparency, leading to an increased interest in eco-friendly materials. Yet, the industry grapples with the technicality of sourcing sustainable options without raising costs.

In addition, safety concerns linger. Contamination during packaging can lead to serious implications. A study indicated that nearly 30% of meat products face cross-contamination risks. This statistic raises questions about current packaging practices. While technology advances, the industry must reflect on how to optimize packaging solutions for both freshness and safety, ensuring consumer trust remains intact.

Importance of Freshness and Safety in Meat Packaging

In the food industry, maintaining the freshness and safety of meat products is vital. Consumer preferences lean heavily toward fresh, high-quality meat. According to industry reports, around 70% of consumers discard meat soon after the sell-by date, demonstrating a strong concern for safety. Effective packaging solutions are critical for extending shelf life and preventing spoilage.

Innovative packaging methods, such as vacuum sealing and modified atmosphere packaging, are gaining traction. These techniques can reduce spoilage rates significantly. Studies show that properly packaged meats can retain freshness up to 50% longer than traditional methods. However, not all packaging solutions are uniformly reliable. Some materials may still allow for microbial growth despite their protective features. This inconsistency calls for better standards and regular assessments of packaging efficacy.

Moreover, transparency plays a key role in consumer trust. Many customers want to know how their meat is packaged. They seek clarity on safety standards and shelf-life information. Yet, studies indicate that only 40% of consumers feel adequately informed about packaging technologies. As the industry progresses, the focus should be on enhancing how information is communicated. Creating better awareness can help consumers make informed choices about meat safety and freshness.

Types of Materials Used in Meat Packaging

Meat packaging plays a critical role in maintaining freshness and safety. Different materials serve various purposes. Commonly used options include plastic wraps, vacuum bags, and trays. Each has unique benefits for preserving meat quality. Plastic wraps can provide a thin barrier, reducing exposure to air. However, they may not be as effective against moisture loss.

Vacuum packaging is another popular method. This involves removing air from the package, which slows down spoilage. It's great for extending shelf life. Yet, improper sealing can lead to bacterial growth. Trays, often made from polystyrene, are designed for convenience. They are easy to stack and store. However, they do not always offer the best protection against physical damage.

Choice of materials impacts not only freshness but also safety. Some materials can leach chemicals, which raise concerns. While many are deemed safe, ongoing research is essential. The food industry must focus on innovations that enhance both preservation and safety. Balancing cost and quality is a persistent challenge. Finding that perfect solution requires ongoing reflection and adaptation.

Innovative Technologies in Meat Packaging Solutions

Innovative technologies are transforming meat packaging solutions, increasing freshness and safety. According to a recent report by MarketsandMarkets, the global meat packaging market is projected to reach $20 billion by 2027. New materials and techniques are crucial for extending shelf life and maintaining quality.

Active packaging is one of the most exciting innovations. It involves incorporating substances that either absorb oxygen or release antimicrobial agents. This can reduce spoilage and improve safety. Additionally, smart packaging technology includes sensors that monitor freshness in real time. These sensors can alert producers and consumers about potential spoilage. However, many companies still face hurdles in adopting such technologies, often due to cost concerns.

Modified atmosphere packaging (MAP) is another effective solution. It replaces the air around meat with gases like nitrogen and carbon dioxide. This method slows down microbial growth and preserves color. However, implementing MAP requires precision and knowledge about optimal gas mixtures. Many producers may struggle to find the right balance, which can impact quality. As the industry evolves, the need for innovative yet affordable solutions continues to grow. The challenge lies in making these advancements accessible to all stakeholders in the food industry.

Top Meat Packaging Solutions for Freshness and Safety in the Food Industry

| Packaging Type | Key Features | Benefits | Shelf Life Extension |

|---|---|---|---|

| Vacuum Packaging | Removal of air, sealing | Prevents oxidation, spoilage | 2-3 weeks |

| Modified Atmosphere Packaging (MAP) | Gas flush, controlled atmosphere | Maintains color, extends shelf life | 2-4 weeks |

| Cryovac Packaging | Sealed barrier technology | Retains moisture, flavor | 1-2 months |

| Active Packaging | Oxygen scavengers or moisture absorbers | Enhances food safety | Varies based on application |

| Biodegradable Packaging | Eco-friendly materials | Reduces environmental impact | 1-2 weeks |

Regulatory Standards and Best Practices for Meat Packaging

In the meat industry, safety and freshness are paramount. Regulatory standards dictate how products should be packaged. Efficient packaging helps maintain quality during transport and storage. Companies must keep up with guidelines set forth by health organizations. These regulations cover materials, labeling, and hygiene practices.

Tips: Always check local regulations. Understanding the rules can prevent costly mistakes. Attend workshops on best practices. Learning from experts can improve your processes.

Using the right materials is crucial. Packaging must protect against contamination. Vacuum sealing is a common method. It reduces oxygen levels, extending shelf life. However, not all meats suit this method. Some may require breathable packaging. Researching options can lead to better decisions.

Products should be labeled clearly. Include expiration dates and handling instructions. This helps consumers make informed choices. However, remember that compliance doesn't guarantee safety. Regular audits and employee training improve overall quality. Continuous reflection on practices is essential for success.

Related Posts

-

Top 10 Meat Packaging Solutions for Freshness and Safety

-

Top Press Solutions in 2025 for Effective Public Relations Management

-

How to Choose the Best Food Packaging Solutions for Your Business Needs

-

Top 10 Trends Shaping the Future of the Packaging Equipment Market

-

How to Choose the Best Packaging Solutions for Your Business Needs

-

Top Packaging Machines Trends to Watch in 2025 for Your Business