2025 Top Meat Wrapping Machines: Choosing the Best for Your Business

In the evolving landscape of the meat processing industry, the deployment of advanced technology has become essential for enhancing efficiency and maintaining product quality. Among the critical equipment, meat wrapping machines play a pivotal role in preserving the freshness and extending the shelf life of meat products. According to a recent industry report by MarketsandMarkets, the global meat processing equipment market is projected to reach USD 20.46 billion by 2025, with a significant portion of this growth driven by innovations in packaging technologies.

As businesses strive to meet increasing consumer demands for convenience and safety, the importance of selecting the right meat wrapping machines cannot be overstated. These machines not only protect products from contamination but also aid in reducing food waste, which is crucial given that approximately 1.3 billion tons of food is wasted globally each year, according to the Food and Agriculture Organization (FAO). Therefore, understanding the various types of meat wrapping machines available in the market and their respective features is imperative for stakeholders aiming to optimize their operations and enhance product appeal.

Investing in high-quality meat wrapping machines can lead to considerable advantages, including cost reductions, improved packaging aesthetics, and ultimately, higher customer satisfaction. As we look towards 2025 and beyond, businesses must carefully evaluate their packaging options to remain competitive in an increasingly demanding marketplace.

Overview of Meat Wrapping Machines in 2025

In 2025, the landscape of meat wrapping machines has significantly evolved, embracing advanced technology to enhance efficiency and adaptability in the food industry. These machines are designed to ensure that meat products are securely packaged, extending their shelf life while maintaining quality. The latest models incorporate features such as automated wrapping processes, real-time monitoring, and even smart connectivity, which allows for seamless integration into existing production lines. Businesses now prioritize machines that can accommodate various types of meat, ensuring versatility to meet diverse customer demands.

Another critical aspect of meat wrapping machines in 2025 is their focus on sustainability. Manufacturers are increasingly incorporating eco-friendly materials into their packaging solutions, reflecting a growing consumer preference for environmentally responsible products. These machines not only reduce waste but also utilize energy-efficient technologies, helping businesses lower their carbon footprint. As the market continues to expand, it's essential for operators to consider both the operational efficiency and the environmental impact of the machinery they choose, ensuring they stay competitive while contributing positively to the planet.

2025 Top Meat Wrapping Machines: Choosing the Best for Your Business

| Machine Type | Wrapping Speed (Packages/min) | Film Type | Dimensions (L x W x H) | Weight (kg) | Power (kW) | Price Range (USD) |

|---|---|---|---|---|---|---|

| Automatic Gravitational Wrapper | 40 | PVC | 200 x 100 x 150 cm | 150 | 3.5 | 3000 - 5000 |

| Semi-Automatic Vacuum Sealer | 25 | PA/PE | 100 x 50 x 80 cm | 80 | 2.0 | 1500 - 2500 |

| Fully Automated Shrink Wrapper | 60 | LDPE | 250 x 120 x 160 cm | 200 | 4.0 | 5000 - 8000 |

| Manual Hand Wrapper | 10 | Polyolefin | 50 x 30 x 20 cm | 15 | 0.5 | 100 - 300 |

Key Features to Consider when Choosing a Meat Wrapping Machine

When selecting the best meat wrapping machine for your business, there are several key features to consider. First and foremost, the machine’s sealing technology is crucial. A reliable sealing mechanism not only enhances the freshness of the meat but also prevents contamination. Look for machines that offer adjustable temperature settings and pressure controls to accommodate various types of meat and wrapping materials.

Another important aspect to consider is the machine's capacity. Evaluate your production volume to choose a machine that can handle your workload efficiently without compromising quality. Advanced models often come with automated functions, which can significantly increase productivity and reduce labor costs.

Tips: Always assess the machine’s ease of use and maintenance. A user-friendly interface can save time during operation, while easy cleaning and maintenance features will ensure your machine remains in top condition. Moreover, consider investing in a machine with energy-efficient technology to minimize operational costs. Remember, the right meat wrapping machine can streamline your processes and contribute to better product quality.

Top Brands and Models of Meat Wrapping Machines in 2025

When considering the best meat wrapping machines for 2025, businesses must evaluate the latest models that combine efficiency and durability. The top brands are focusing on technological advancements, such as automated wrapping systems that significantly reduce labor costs and enhance packaging speed. Additionally, energy-efficient designs are gaining traction, allowing businesses to reduce their environmental footprint while maintaining high productivity.

In terms of specific features, look for machines that offer versatile wrapping options to accommodate various product sizes and types. Many of the leading models now include user-friendly interfaces, making it easier for staff to operate and adjust settings for different packaging needs. Furthermore, durability remains a critical factor, with high-quality materials designed to withstand the rigors of daily use in a fast-paced environment.

As the demand for quality meat products continues to rise, investing in the right technology will be essential for businesses aiming to stay competitive.

Comparative Analysis of Still vs. Vacuum Meat Wrapping Techniques

When considering meat wrapping techniques for your business, the choice between still and vacuum wrapping is pivotal. Still wrapping, often utilizing classic film, is straightforward and cost-effective. It allows customers to see the product while providing a decent level of protection. However, it offers limited shelf life, as it may not effectively prevent air exposure, leading to quicker spoilage. This technique is suitable for businesses that prioritize immediate sales and freshness over long-term storage.

On the other hand, vacuum wrapping uses specialized machinery to remove air from the packaging, significantly extending the meat’s shelf life. This method prevents oxidation and bacterial growth, ensuring that the meat remains fresher for a longer period. It is ideal for businesses that require storage flexibility or wish to transport products over longer distances. While the initial investment in a vacuum machine can be higher, the return on investment often justifies the cost, particularly for high-volume operations.

Tips: When deciding between these techniques, consider your target market. If you sell primarily to local customers, still wrapping may suffice. However, if you plan to expand your reach or offer products online, the investment in vacuum packaging technology could enhance your brand's reputation for quality. Additionally, ensure that staff is properly trained on both techniques to maximize efficiency and minimize waste.

Best Practices for Maintenance and Operation of Meat Wrapping Machines

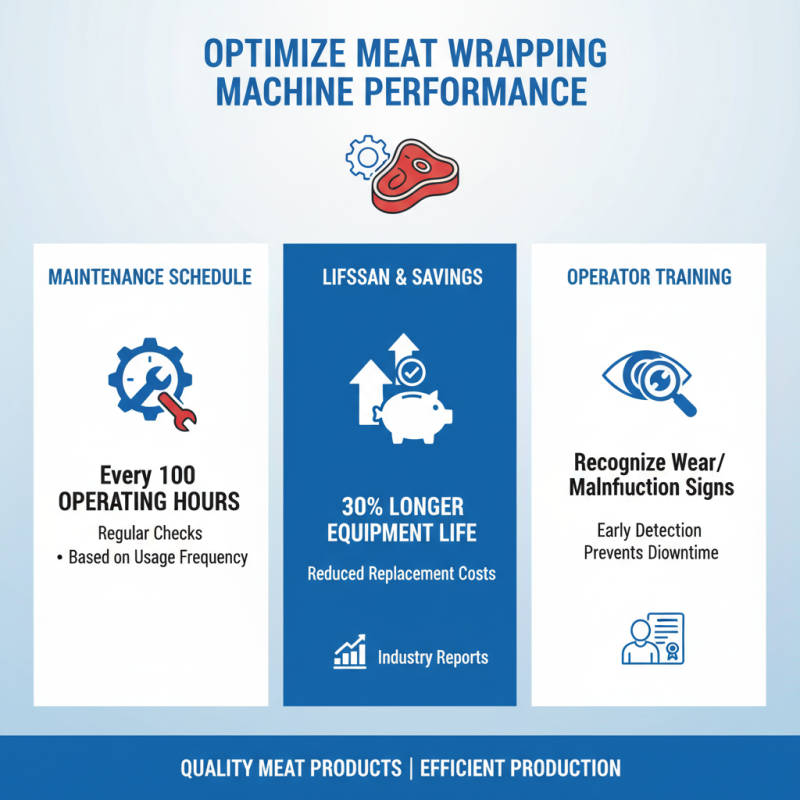

Maintaining and operating meat wrapping machines effectively is crucial for ensuring the quality of meat products and optimizing production efficiency. Regular maintenance checks should be scheduled based on usage frequency; typically, machines should be serviced every 100 hours of operation. According to industry reports, proper maintenance can enhance equipment lifespan by up to 30%, reducing the need for costly replacements. Additionally, operators should be trained to recognize signs of wear or malfunction, as early detection can prevent significant downtime.

Moreover, best practices for operating these machines include ensuring that all settings are calibrated according to the specific types of meat being processed. For instance, studies have shown that incorrect temperature settings can lead to spoilage and significantly decrease shelf life. It is also essential to maintain cleanliness and sanitation standards, as contamination risks can arise during the wrapping process. Regular cleaning schedules should be adhered to, following manufacturer guidelines to ensure both safety and operational efficiency. Reports suggest that facilities adhering to strict maintenance protocols have experienced up to a 25% increase in productivity, highlighting the importance of best practices in the meat wrapping industry.

Related Posts

-

How to Choose the Best Food Packaging Solutions for Your Business Needs

-

What are the Best Packaging Solutions International for Your Business Needs

-

Top US Packaging Solutions to Streamline Your Business Operations

-

10 Best European Packaging Solutions for Sustainable Business Growth

-

Top 10 Meat Packaging Solutions for Freshness and Safety

-

How to Choose the Best Packaging Solutions for Your Business Needs