Top 10 Trends Shaping the Future of the Packaging Equipment Market

As the packaging equipment market continues to evolve, understanding the trends shaping its future becomes vital for industry stakeholders. Renowned expert Dr. Emily Zhang, a leading analyst in packaging technologies, asserts, "The acceleration of digitalization and sustainability initiatives are not just trends; they are the core drivers of the packaging equipment market." This statement underlines the importance of recognizing how these key factors influence businesses and their operational strategies.

In recent years, several emerging trends have begun to define the landscape of the packaging equipment market. From advancements in automation and smart technologies to an increasing emphasis on eco-friendly materials, companies must adapt to stay competitive. As businesses pivot towards more innovative solutions, the role of packaging equipment becomes essential in meeting consumer demands while ensuring efficiency and sustainability.

By examining the top 10 trends currently shaping the packaging equipment market, we can gain valuable insights into how these changes are impacting production processes, consumer preferences, and the environment. This exploration not only highlights the importance of innovation but also emphasizes the need for businesses to remain agile in a fast-paced market scenario.

Emergence of Smart and Connected Packaging Technologies

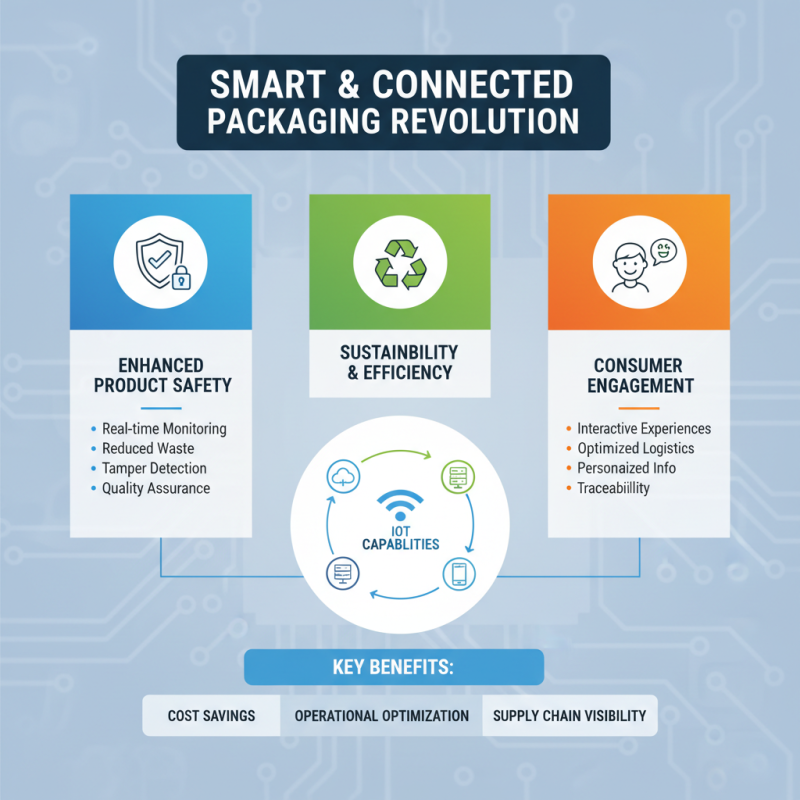

The emergence of smart and connected packaging technologies is revolutionizing the packaging equipment market, enhancing product safety, sustainability, and consumer engagement. These advancements leverage IoT (Internet of Things) capabilities, allowing packaging to communicate real-time data regarding product integrity, environment conditions, and even user preferences. As a result, manufacturers can monitor supply chain logistics more effectively, respond to potential disruptions, and optimize inventory management, leading to cost savings and increased operational efficiency.

Furthermore, smart packaging empowers consumers by providing interactive features, such as QR codes or NFC (Near Field Communication) tags that can be scanned for additional product information, usage instructions, or promotional content. This level of connectivity not only fosters a deeper connection between brands and customers but also meets growing consumer demand for transparency and traceability in product sourcing and safety. Additionally, environmentally conscious innovations, such as biodegradable sensors and recyclability features, are being integrated into packaging, addressing the pressing challenge of sustainability and supporting businesses in their efforts to reduce their ecological footprint.

Sustainability Practices Driving Packaging Equipment Innovations

Sustainability practices are playing a transformative role in the evolution of the packaging equipment market. Companies are increasingly recognizing the need to reduce their environmental impact, prompting innovations that focus on eco-friendly materials and processes. This shift is not merely a trend; it has become a critical component of strategic planning for manufacturers. As a result, packaging equipment is now being designed to accommodate renewable materials, minimize waste, and enhance recyclability. Advanced technologies such as biodegradable films, compostable substrates, and water-based adhesives are becoming common, enabling businesses to meet consumer demand for greener options without sacrificing performance.

Moreover, sustainability is driving the advancement of automation and smart technologies within the packaging sector. With the rise of Industry 4.0, companies are integrating data analytics and IoT solutions to optimize the efficiency of their packaging operations. This not only reduces energy consumption but also minimizes excess resources and materials used in production. Enhanced tracking systems are enabling better supply chain transparency, allowing consumers to make informed choices based on the sustainability credentials of a product. Thus, the interplay between sustainability practices and technological innovation is shaping a future where packaging equipment is not only efficient but also aligned with global efforts to create a more sustainable environment.

Integration of Automation in Packaging Processes

Automation integration in packaging processes is revolutionizing the packaging equipment market by enhancing efficiency, accuracy, and productivity. As industries strive for operational excellence, automated solutions are increasingly being adopted to streamline packaging workflows. By minimizing manual intervention, automation reduces the risk of human error while increasing the speed and consistency of packaging tasks. This transition not only improves output rates but also allows companies to optimize their labor costs by reallocating human resources to more complex, value-added activities.

Moreover, advancements in technology such as robotics, artificial intelligence, and the Internet of Things (IoT) are playing a pivotal role in this transformation. Smart packaging systems equipped with sensors and data analytics can monitor production in real-time, leading to informed decision-making and proactive maintenance. This connectivity helps manufacturers anticipate needs and respond swiftly to market demands, ensuring that they remain competitive in a rapidly changing landscape.

As a result, the future of packaging equipment looks increasingly interconnected and automated, setting the stage for innovations that will redefine the industry.

Growth of E-commerce and Its Impact on Packaging Equipment Demand

The rise of e-commerce has significantly reshaped the packaging equipment landscape, fueling demand for innovative and efficient solutions. As online shopping continues to grow, businesses are compelled to adapt their packaging strategies to meet the expectations of consumers who seek convenience and sustainability. The need for automated packaging systems that streamline operations and reduce costs has become increasingly crucial. Companies are now more focused on developing packaging equipment that not only enhances product integrity during transportation but also minimizes environmental impact.

Tips: When selecting packaging equipment for e-commerce, consider systems that offer flexibility for various product sizes and shapes. This versatility is essential for efficiently fulfilling diverse customer orders and optimizing storage space. Furthermore, investing in technology that enables real-time tracking can enhance order accuracy and improve customer satisfaction.

As the demand for personalized packaging solutions rises, manufacturers of packaging equipment are innovating to create customizable options. This personalization can include branded packaging that enhances the unboxing experience, making it more memorable for consumers. By leveraging advancements in automation and smart technology, companies can meet increasing market demands while ensuring efficiency and sustainability remain at the forefront of their operations.

Tips: Explore options for modular packaging systems that can easily adapt as your business scales. This will not only save costs in the long run but will also allow you to respond swiftly to changing consumer preferences and market trends.

Adoption of Customization and Personalization in Packaging Solutions

The packaging equipment market is increasingly being shaped by the growing demand for customization and personalization, driven by changing consumer preferences and the rise of e-commerce. According to a recent report by Smithers Pira, the global market for personalized packaging solutions is expected to grow at a CAGR of 6.4%, reaching $503 billion by 2023. This surge in demand reflects a broader trend where consumers are seeking unique and individualized products, prompting manufacturers to adopt flexible packaging equipment that can accommodate short production runs and rapid changes in design.

Customization in packaging not only enhances brand identity but also improves customer engagement. A survey conducted by McKinsey revealed that 70% of consumers are willing to pay a premium for personalized packaging experiences. As companies strive to stand out in a crowded marketplace, packaging equipment that can easily integrate digital printing technology and modular systems becomes essential. This flexibility allows brands to launch targeted campaigns quickly, adapting to seasonal changes or specific customer demographics without significant delays, thus ensuring competitiveness in the dynamic retail landscape.

As businesses increasingly recognize the importance of innovative packaging strategies, investment in advanced packaging equipment is expected to rise. The Research and Markets report indicates that by 2025, the spend on automation and smart packaging technologies could exceed $20 billion. These trends not only highlight the necessity for timely production adjustments but also indicate a pivotal shift toward sustainable and efficient packaging solutions that cater to the personalized needs of consumers, further solidifying customization as a key focus for the future of the packaging equipment market.

Top 10 Trends Shaping the Future of the Packaging Equipment Market

Related Posts

-

Top US Packaging Solutions to Streamline Your Business Operations

-

How to Choose the Best Packaging Solutions for Your Business Needs

-

Top 10 Meat Packaging Solutions for Freshness and Safety

-

10 Best European Packaging Solutions for Sustainable Business Growth

-

How to Choose the Best Food Packaging Solutions for Your Business Needs

-

2025 Top Meat Wrapping Machines: Choosing the Best for Your Business